A drill press is a machine used to cut holes into metal, wood and other materials. Drill presses come in various shapes and sizes, including floor standing units, benchtop drill presses and magnetic drill presses. Most drill presses are operated by turning a handle which moves the head of the machine with a drill attached down into the work piece.

If you already know which type of drill press you’re looking for, choose one of the quick links below. If not, read more below about the different types of drill press and see our full buyers guide to find the best one for your needs whether you’re a woodworker or welder.

- Best benchtop drill press

- Best benchtop drill press for metal

- Best floor standing drill press

- Best drill press under $200

- Best cheap drill press

- Best magnetic drill press

Benchtop drill press: These can be fixed to your workbench and take up less space in your work space. This are generally good value for money and are a good option if you’re working in a smaller work space.

Floor standing drill press: These heavier units are grounded floor columns. These are high powered but will need a dedicated area in your work space.

Contents

Best Benchtop Drill Press

1. WEN 4214 Bench-top Drill Press

![]() Best All-Round

Best All-Round

|

|

The Wen 4214 is our favorite drill press for all round features and value for money. The cast iron drill press is well-built and features a variable speed of 580-3200 RPM so you can simply move the lever on the side of the machine to adjust the speed when you’re drilling. The digital display shows exactly what RPM you’re working at so you can fine-tune it to the perfect settings. Another cool feature is the laser which shows you exactly where on your workpiece you’re going to drill. The worktable tilts 45° left and right to help working at difficult angles. It’s also a big enough size for most projects and boasts a 12 inch swing and 5/8 inch chuck. It’s an affordable and versatile drill press that great for most home woodworking and metalworking projects.

|

Specifications

|

Pros

Cons

|

2. JET J-2530 Bench-top Drill Press

![]() Best for Metalwork

Best for Metalwork

|

|

The J-2530 is a solidly built drill press that’s designed for stability and versatility and has the power and RPM to work on a wide range of metal projects as well as wood. It offers a wider range of speeds than any other drill press in its class. The speeds aren’t variable but there are 16 to choose from so you can find the one that’s best for your application. The J-2530 also has a lot of power with a 3/4HP motor and can be rewired to 230V by following their instruction manual. There are also four permanently lubricated ball bearings that support the spindle to help maintain accuracy when drilling. This drill press is more expensive but everything is solidly built with iron and steel and it’s perfect for drilling metal.

|

Specs

|

Pros

Cons

|

3. Shop Fox W1668 Drill Press/Spindle Sander

|

|

This is a more affordable alternative to the J-2530 that still offers a wide RPM range so it’s suitable for a variety of applications, boasting a 3/4 inch drill capacity for steel. One of the standout features of the W1668 is that is doubles up as an oscillating sander which you can convert to in just a few seconds, saving you the need for two machines. Sanding drums and sandpaper comes with the machine and there is a clearance hole in the table with a dust collection port to make it less messy. It’s a powerful and well-built machine that’s suitable for a range of applications.

|

Specs

|

Pros

Cons

|

4. WEN 4212 Bench-top Drill Press

![]() Best Under $200

Best Under $200

|

|

The WEN4212 is our favorite drill press under $200. It’s similar to the 4214 but it’s a smaller, more lightweight version. It still has a some of our favorite features such as the easily adjustable the variable drill press, laser crosshairs and digital speed display. Which are great features for the price. The 4212 has a smaller swing, spindle travel, weight, height and table size than the 4214 so is only really suitable for smaller projects. This is a reliable drill press if you don’t need a machine for heavy metal projects but want some great features.

|

Specs

|

Pros

Cons

|

5. WEN 4208 Bench-top Drill Press

![]() Best Cheap Drill Press

Best Cheap Drill Press

|

|

The 4208 is a really basic drill press that’s available for next to nothing and you get a lot for your money. Out the box it’s easy to put together and it’s easy to see why this is a bestselling drill press. It’s pretty lightweight though so you’ll want to bolt of to your workbench. It’s not well suited to large metal drilling operations but will do the job on most usual hobbyist projects. Overall it’s perfect if you just want something simple that runs smooth and will make holes in small projects at minimal cost.

|

Specs

|

Pros

Cons

|

Best Floor Standing Drill Press

1. WEN 4225 Floor Standing Drill Press

![]() Best All Round

Best All Round

|

|

Floor standing drill presses take up more room, but that’s not a bad thing if you’re going to be working on bigger projects. The WEN 4225 has a larger height, spindle travel, swing and table size than almost all benchtop drill presses. It features the usual cool WEN features like the laser point to help improve your precision, digital speed readout and variable speed. It also has an adjustable worklight on the side to help you see what you’re doing easier. The table and base are made from solid cast iron to help offer stability for when you’re testing out its full force of the 8.6 amps power.

|

Specs

|

Pros

Cons

|

2. JET 354170/JDP-20MF Floor Drill Press

![]() Best Professional

Best Professional

|

|

If you’re a little bit more serious about your drilling then there’s no better option that this beautifully crafted powerhouse from JET. This heavy duty drill press boasts a 1.5HP motor and weighs 282 pounds. The spindle is supported by ball bearings to keep it running smooth. In terms of dimensions, it has a huge 20 inch swing and a large 18 x 16 inch table that can be easily adjusted by turning the crank. It has the widest RPM range of any drill press in its class at 150 to 4200 RPM which makes it extremely versatile. This is so well build and can do such a range of projects that you might never need to buy another drill press again.

|

Specs

|

Pros

Cons

|

3. Shop Fox W1848 Oscillating Floor Drill Press

|

|

The Shop fox W1846 is the floor standing model of the W1668 and is very similar in terms of price and specifications. Just like the benchtop model, this features an oscillating spindle sander with sanding drums included. You can easily switch the machine to the sanding operation for easy and effective contour sanding. It features the same RPM range of 250-3050 so has the versatility for most home projects in woodworking and metalworking.

|

Specs

|

Pros

Cons

|

4. JET J-2500 Floor Model Drill Press

|

|

The JET 2500 is the more affordable younger brother of the JET JDP-20MF. It’s not as heavy duty but it’s still solidly built with a steel column, cast iron base and cast iron head. Inside the head is permanently lubricated ball bearing assembly for accuracy and durability. The speed isn’t variable but there are 16 different speeds you can easily change between which makes it one of the most versatile in its class. Overall this is a durable and reliable option for those who don’t need the industrial strength of the JDP-20MF but want something that’s solidly built.

|

Specs

|

Pros

Cons

|

What to Look for in a Drill Press

Drilling Speeds

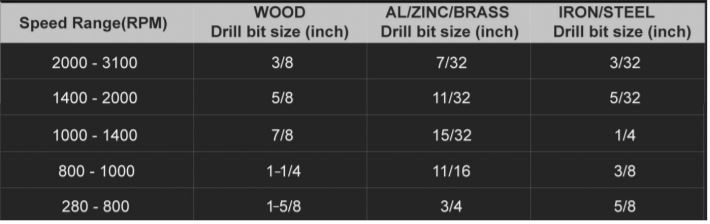

The speeds at which your drill press will operate will determine the range of operations you can perform and the quality of your results.

The revolutions per minute (RPM) will indicate how fast and slow the drill can operate. The number of speeds indicates how many different speed settings there are within that range. If the speed is ‘variable’ then you can set whichever speed you like within the RPM range. Variable speed and a wide RPM range are great features for allowing diversity to achieve the best results. An easily adjustable speed control certainly makes life easier.

The optimal drilling speed for your hole will depend on:

- Material you’re drilling. Harder materials require lower speed, softer materials require higher speed.

- Size of hole required. Larger drill bits require lower speed, and smaller drill bits require higher speed.

Dimensions

When choosing the best drill press, you can’t go wrong by getting the largest you can afford or have room for. You might as well make sure you’ve got it’s big enough because you don’t know what you might be working on in the future. Below are some of the important dimensions measurements explained

Swing

The swing is the distance from support column to the center of the drill (spindle). A drill press with a 10 inch swing will be able to drill a hole in the middle of a circle with a 20 inch diameter. If you’re working on materials with large surface area you’ll need a large swing. The upper swing range is approximately 15-20 inches.

Spindle Travel

‘Spindle travel’ or ‘quill travel’ is the maximum depth of hole that you can drill with the drill press. If the spindle travel is 3 inches then the maximum hole you can drill is 3 inches deep.

Table Size

The table is where you place your workpiece and clamp it in place. The table is attached to the column. Bigger tables make life easier when drilling larger materials as the workpiece is more stable.

Price

One of the biggest differentials between the cheaper models and the premium models is how well they hold up over time. If you’re looking for something that you’re only going to use a few times a year then you’ll be fine with a cheaper model.

Laser

Some drill presses come with laser crosshairs to help you with your accuracy when drilling. This feature isn’t needed, but it’s a cool tool that once you’ve used you’ll love it as it instantly gives you pin point accuracy without needing to lower the drill to check if it lines up.

How to Use a Drill Press

Drilling Metal

The drill can get very hot when drilling metal. Always add a bit of oil to the tip of the drill to lubricate it and help prevent overheating. Use a center punch on the hole to prevent the drill from slipping on the oil.

The harder the metal and larger the drill, the lower speed you should be using. If you can’t get a low RPM then it will be hard to keep it stable. Make sure you use metal piercing twist drill bits and ensure all metal is securely clamped and blocked to prevent any movement.

Machine Table Vice

Never hold metal in your hand when drilling it. The metal could easily catch on the drill and spin out of control and cause a lot of damage.

A table vice is a great tool that helps to keep your workpiece secure so it remains stable and aligned for the drill. You will place the workpiece in between the two jaws of the vice and tighten it so it can’t move. You can also consider clamping the workpiece to hold it in place.

Caring for Your Drill Press

Follow your drill press manufacturer’s guidelines for maintaining the machine. Usually this will consist of ensuring the machine is adequately lubricated. Oil will help to prevent rust and will help to reduce friction between the mechanisms. Make sure that the parts are clean and there is no build up of dirt or grit. Switch off and unplug the power supply before maintaining the drill press.

Drill Press Safety Tips

Always follow your manufactures guidelines and never use any of this advice as a substitute for manufacturer guidelines. Drill presses are dangerous machines and should only be used when following safety procedures outlined by the manufacturer’s handbook. A few safety tips to consider are:

- Never clean away wood chips or metal shavings with your hand.

- Keep hands and fingers away from the drill.

- Don’t make changes to the machine whilst it’s switched on or plugged in.

- Don’t hold the workpiece with your hand, use a device to secure it firmly in place.

- Always wear correct eye and ear protection.

- Don’t wear any loose clothing that could catch on the drill.

- Keep all guards in place.

- Follow manufacturer’s guidelines at all time.

(5.0 / 5)

(5.0 / 5) (4.5 / 5)

(4.5 / 5) (4.8 / 5)

(4.8 / 5) (4.0 / 5)

(4.0 / 5) (4.7 / 5)

(4.7 / 5) (4.6 / 5)

(4.6 / 5) (3.5 / 5)

(3.5 / 5) (4.1 / 5)

(4.1 / 5)