Flash butt welding is a resistance welding process where workpieces are welded together over the entire area of abutting surfaces by the heat obtained from resistance to electric current between the two surfaces, and by the application of pressure after heating is substantially completed.

The term flash welding derives its name from the flash produced during the process. Flash welding was developed from resistance butt welding by accident in attempts to increase the capacity of the butt welding machines by raising the voltage and applying pressure intermittently.

How Flash Butt Welding Works

The sequence of operations required for flash welding is given below:

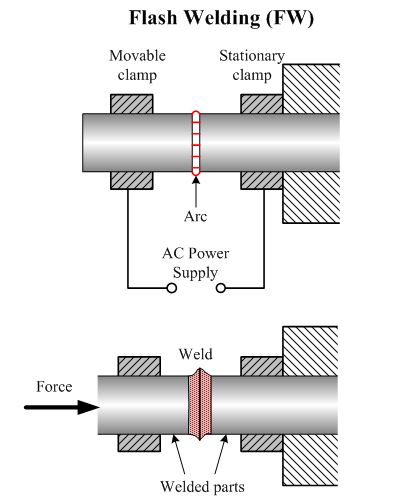

Step 1: Flash butt welds are made on a machine having one stationary and one opposing movable clamp. These clamps securely hold the two workpieces to be welded while simultaneously serving to conduct the welding current through these workpieces.

Step 2: The workpiece held in the movable clamp is brought towards the one gripped in the stationary clamp until the two come in light contact, and as the welding current (with voltage sufficiently high) is turned on, flashing is established.

While incandescent metal particles are being expelled by flashing, the movable platen keeps on moving constantly toward the stationary one at a carefully controlled and accelerated rate.

As the flashing continues, the ends of the two workpieces burn off as they reach a higher and higher temperature until finally they attain the welding temperature

Step 3: At this stage, the pressure of the moving clamp is quickly and greatly increased to forge the parts together and expel the molten metal and slag out of the joint thereby making a good solid weld. The metal expelled forms a ragged fin or flash round the joint which is removed later on by cutting or grinding.

Step 4: The welding current is cut off and the workpieces are unclamped as the fusion weld cools.

Advantages of Flash Welding

- Many dissimilar metals with different melting temperatures can be flash welded.

- Flash welding offers strength factors up to 100%.

- Generally no special preparation of the weld surface is required.

- Flash welding can be used for the welding of those highly alloyed steels which cannot be welded satisfactorily by any other process.

- Under correctly controlled conditions, the heating is not only even but extremely local, so that the cooling stresses are maintained at a minimum; this avoids hardening and cracking in highly alloyed steels.

- The cost of current per weld is small.

- Flash welding is faster than many other methods.

- Flash welding gives a smaller upset

Disadvantages of Flash Welding

- The most undesirable feature of flash welding is the flashing operation during which it is impossible to protect the welding machine and the surrounding area from these particles, which can burn into slide way bearings, insulation etc. This necessitates more frequent maintenance.

- The process presents a considerable fire hazard. Operators need be protected from flying particles.

- Concentricity and straightness of workpieces during welding is often difficult to maintain.

- Metal is lost during flashing and upsetting.

- Shape of the workpieces to be flash welded should be similar.

- It is generally not recommended for welding zinc and its alloys, cast iron, lead and its alloys.

Applications of Flash Welding

- Flash welding is applied primarily in the butt welding of metal sheets, tubing, bars, rods, forgings, fittings etc.

- Flash butt welding is commonly used to join railway rails

- Flash welding finds applications in automotive and aircraft products, household appliances, refrigerators and farm implements.

- The process is also used for welding the band saw blades into continuous loops, and joining of tool steel drill, tap and reamer bodies to low carbon steel and alloy steel shanks.

- Flash welding is used to produce assemblies that otherwise would require more costly forgings or castings.

Metals Welded by Flash Welding

- Low carbon steels.

- Medium strength and high strength low alloy steels.

- Tool steels.

- Stainless steels.

- Aluminium alloys (with thickness greater than 1.25 mm).

- Copper alloys (with high zinc content).

- Magnesium alloys.

- Molybdenum alloys.

- Nickel alloys.

- Titanium alloys.

Difference Between Flash Welding and Upset Butt Welding

In upset welding no arcing (and hence flashing) takes place between the surfaces being joined. Heat is produced solely by the electrical resistance at the abutting surfaces due to the passage of an electrical current.

Flash welding consumes much less welding current than consumed by upset butt weld process; the time allowed for weld to be completed is, however, more.

In flash welding heat application precedes the pressure whereas in butt welding constant pressure is applied during the heating process which eliminates flashing.