MIG welding with shielding gas helps produce high quality welds as you prevent the weld pool from being exposed to elements in the atmosphere which will contaminate the weld and produce weld defects including porosity and spatter.

There are different types of MIG welding gas to choose from, all suitable to different requirements. This guide explains how to find the right shielding gas mix by explaining the gases available and their properties.

Contents

What gas is used for MIG welding?

The most common gases used when MIG welding are Carbon Dioxide, Argon, Oxygen and Helium, these will often be used as a mixture of two gases in the same gas cylinder.

The two most frequently used MIG shielding gases for mild steel are a 75% argon 25% CO2 mixture and pure CO2. Pure CO2 is a cheaper option but produces lower quality welds.

Different gases suit different requirements so you need to evaluate which gas mixture is best for your needs. The cost of the gas and the quality of the weld are two of the main factors to consider when choosing a MIG shielding gas. We have explained the different types of gases and the MIG applications they are most suited for below.

Argon and Carbon Dioxide (CO2) Mix

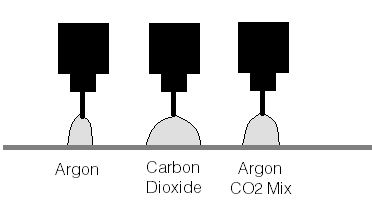

An Argon and CO2 gas mixture is a popular shielding gas mixture which has higher weld quality and less spatter than pure CO2. The presence of argon helps to narrow the penetration, provide much greater arc stability and reduce spatter, producing a smooth spray arc transfer.

Argon and CO2 mix will usually contain between 75% and 95% Argon and between 5% and 25% CO2. Mixtures with higher CO2 will produce more spatter, however, mixtures with Argon over 80% can have an arc which becomes too fluid and hard to control, which is particularly problematic if you’re performing out of position welding.

An Argon and CO2 mix is more expensive than pure CO2. If weld quality and appearance isn’t as important as reducing material costs then look at pure CO2. Argon CO2 mix is good choice if you want to reduce post weld cleanup time.

Argon/CO2 mix summary:

- Less spatter

- Reduced clean up time

- Expensive

- High weld quality

Pure Carbon Dioxide (CO2)

CO2 is the least expensive shielding gas which makes it a popular choice of MIG welding gas where low material costs is an essential consideration.

The main problem with CO2 is that the arc is less stable than other gas mixes and it produces lots of spatter. If you need to spend time cleaning the welds you could actually have increased costs, but if aesthetics aren’t important then it’s a good choice.

CO2 is hot and does provide deep penetration, which makes it a good choice for thicker metals or if you want to get the most penetration out of a 110V MIG welder, but stay away if you’re welding thin autobody sheet metal. If you want to get better quality welds with CO2 you can buy an Argon and CO2 mix for higher quality welds.

Pure CO2 summary:

- Cheap

- Deep penetration

- Lots of spatter

- Not suitable for thin metal

Pure Argon

Pure Argon gas can be used to MIG weld but only if you’re welding a non-ferrous metal such as aluminum, magnesium or titanium. Welding aluminum and other non-ferrous metals should use 100% Argon shielding gas for the best quality welds. Argon and helium is the second most common mixture for non-ferrous metals, followed by pure helium.

Pure Argon is not recommended for welding steel and will not give enough thermal conductivity to MIG weld ferrous metals. If you try MIG welding steel with 100% argon you won’t get adequate penetration or fusion and the weld will be weak.

Pure Argon summary:

- Best for non-ferrous metals

- Not suitable for steel

Argon and Helium mix

Helium is primarily used when MIG welding non-ferrous metals to increase heat. Helium provides a very wide penetration and has a higher flow rate than argon so it’s possible to have a greater welding speed than pure argon.

Helium is more expensive, but you may be able to offset the material costs with increased productivity and reduced labor costs. The percentage of helium used can range from 25% to 75%, with more helium providing wider penetration and travel speed.

Generally, a higher percentage of helium is required for thicker base metal. 75% helium would only really be used to weld aluminum of thickness 1 inch and above in the flat position.

Argon and Helium mix summary:

- Best for non-ferrous metals

- Wide penetration

- Fast welding speed

Pure Helium

Helium can be used on its own for MIG welding non-ferrous metals, however, this is better for TIG welding with electrode negative. High helium content is best used for MIG welding on thicker materials. Welding speed can be increased high to increase productivity, however it is expensive and is very rarely used compared to argon and helium argon mixes.

Pure Helium Summary:

- Best for non-ferrous metals

- Suitable for thick base metal

- Rarely used

Argon and Oxygen mix

Oxygen is never used as a base gas but can be mixed in amounts of typically 1% – 5%. Small amounts of oxygen can be mixed with argon and CO2 because it helps stabilize the arc, improve the weld pool fluidity, and improve the quality of the weld and penetration. The downside of oxygen is that it causes oxidation of the metal, so should not be used when welding aluminum, magnesium or copper. Oxygen and argon is typically used for spray transfer on stainless steel to help produce a stable arc, however the increased weld pool fluidity can make welding out of position problematic.

Argon and Oxygen mix summary:

- Can cause oxidation in aluminum, magnesium and copper

- Helps stabilize the arc